For todays pouring 120 lbs of bronze are melted in the furnace.

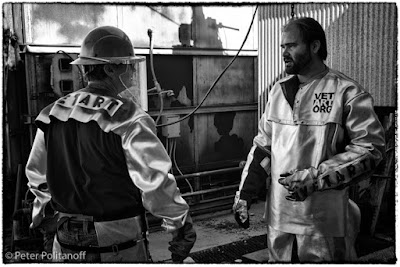

Academy founder, Brandon Roy outlines the order of the steps in the procedure.

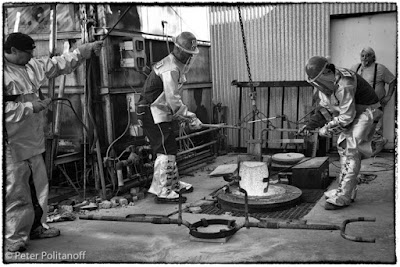

Impurities in the liquid are removed by adding salt and piece of glass, this forms a slag which is easily scraped off the top of the molten mass.

Once the bronze has reached temperature and is in a liquid state, the plaster molds are removed from the kiln,

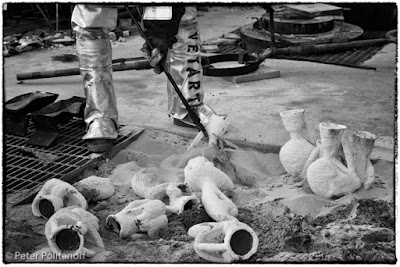

Then placed in dry sand, to keep them upright and in place for the pour.

One of the plaster molds broke while heated in the kiln, the pouring cup had broken off from the mold. Brandon is quickly patching the mold. Since part of the pour was an edition of 5 pieces, it would have meant another several week delay to complete the order.

The crucible with the liquid bronze is raised from the furnace and put into a special yoke.

After the metal has set up the molds are pulled out of the sand, left to cool for an hour or so before the plaster is removed.

Special thanks to Brandon Roy, The California Academy of Sculpture, and VetArt.Org.

As always, all images are copyright Peter Politanoff and may not be reproduced without explicit consent. You are more than welcome however to link to this site.

All images shot with Leica cameras & lenses